Your customers complain that leggings slide down during a run or that a sports bra feels too restrictive. Bad fit leads to returns, negative reviews, and a damaged brand image.

A perfect fit comes from a three-part process. First, match your fabric's stretch and compression to your design. Second, create a precise graded spec sheet. Finally, test every design on a live fit model to check comfort and performance during movement.

In my first few years as a clothing artisan, I thought that if the measurements were correct, the fit would be perfect. I was wrong. A client brought me a sample of a running top that was technically perfect according to the spec sheet, but it rode up the moment the wearer lifted their arms. I realized then that fit is not about static measurements on a table. It is about how a garment lives and moves on a human body. This lesson is at the core of how Wearzio operates today. Achieving the perfect fit is a science, and it is the single most important factor for customer loyalty in activewear.

How Does Fabric Choice Impact Sportswear Fit?

You’ve approved a beautiful design, but the first sample fits terribly. It is either too loose or too tight, and you cannot understand why. The problem is often the fabric you chose.

A pattern is engineered for a specific fabric stretch and weight. If you use a different material, the fit will fail. A compressive fabric requires a smaller pattern, while a lightweight, drapey fabric needs a different cut entirely. Always test your pattern with the final fabric.

The relationship between the pattern and the fabric is everything. Think of it like a car's engine and its fuel. You cannot put diesel in a gasoline engine and expect it to work. The same is true for patterns and fabrics. A brand owner I work with, much like Alex, wanted to create a super compressive legging. Their designer provided a standard legging pattern. We knew from experience that this would result in a loose, unsupportive fit. We had to explain that for high compression, we need to create a pattern with "negative ease," meaning it is actually smaller than the body measurements. The fabric's powerful stretch makes up the difference and creates that "held-in" feeling. Understanding this connection is the first step to mastering fit.

The Science of Stretch and Weight

Every fabric behaves differently. We analyze three main properties to predict how it will fit.

- Stretch Percentage: We measure how much a fabric stretches in both length and width. This is the difference between 2-way and 4-way stretch. A pattern for a 4-way stretch fabric will not work for a 2-way stretch fabric.

- Compression vs. Drape: A heavy, compressive nylon/spandex blend is designed to hug the body tightly. It requires a specific pattern. A lightweight modal fabric is meant to drape loosely. Using the wrong pattern for either would be a disaster.

- Fabric Weight (GSM): GSM stands for Grams per Square Meter. A heavier fabric (higher GSM) will have more structure and less drape, while a lighter fabric will be flowier. This affects how the garment hangs on the body.

| Fabric Property | How It Affects Fit | Example Garment |

|---|---|---|

| High 4-Way Stretch | Allows for a close, body-hugging fit without restricting movement. | High-intensity workout leggings, sports bras. |

| High Compression | Feels supportive and "holds you in." Pattern must have negative ease. | Running tights, shaping activewear. |

| Low Stretch / Woven | Has no give, so the fit must be looser and more structured. | Outerwear jackets, track pants. |

| Lightweight / Drapey | Hangs loosely on the body. Requires a pattern with more volume. | Yoga tops, warm-up layers, loungewear. |

What Is the Role of a Graded Spec Sheet in Getting the Right Fit?

The medium size fits perfectly, but customers complain the XS is tiny and the XL is shapeless. Inconsistent sizing across your range is a quick way to lose customer trust and get returns.

A graded spec sheet, or "grade rule," dictates how a pattern's measurements change for each size. A professional grade rule is not uniform; it scales different points of the garment proportionally. This ensures a consistent fit from your smallest to your largest size.

Many new brands make a critical mistake here. They assume you can just add two inches to every measurement to go from a Medium to a Large. This is how you end up with an XL sports bra with huge armholes that offer no support. The body does not scale uniformly. As a person's chest gets bigger, their shoulder width or arm length does not increase at the same rate. This is where the expertise of a good pattern maker is invaluable. They understand how to apply a grade rule that respects the proportions of the human body across a full-size range. My team and I always review the grade rules to make sure they make sense for the specific garment and the target customer's body type.

Beyond the Base Size

Your journey to a consistent fit starts with a perfect base size (usually a Medium), but it must be followed by smart grading.

- What is Grading? It's the process of creating a full-size range (e.g., XS to XXL) from your approved base size pattern.

- Why Proportional Grading Matters: A good grade rule might increase the chest measurement by 4cm between sizes but only increase the shoulder width by 1cm. This maintains the garment's intended shape and balance.

- Testing Your Grade: The best way to ensure your grading is correct is to order "jump size" samples. If your base size is Medium, you should also get a physical sample made in an XS and an XL. Trying these on a fit model is the only way to be 100% confident in your full-size range before starting mass production.

| Garment Point | Bad Grade (Uniform) | Good Grade (Proportional) |

|---|---|---|

| Chest | +4 cm per size | +4 cm per size |

| Shoulder Width | +4 cm per size | +1 cm per size |

| Armhole Opening | +4 cm per size | +1.5 cm per size |

| Garment Length | +4 cm per size | +2 cm per size |

Why Is a Live Fit Model Essential for Perfecting Activewear Fit?

On paper, the measurements look right. On a mannequin, the garment looks fine. But then you get feedback that it chafes, slips, or becomes see-through during a workout.

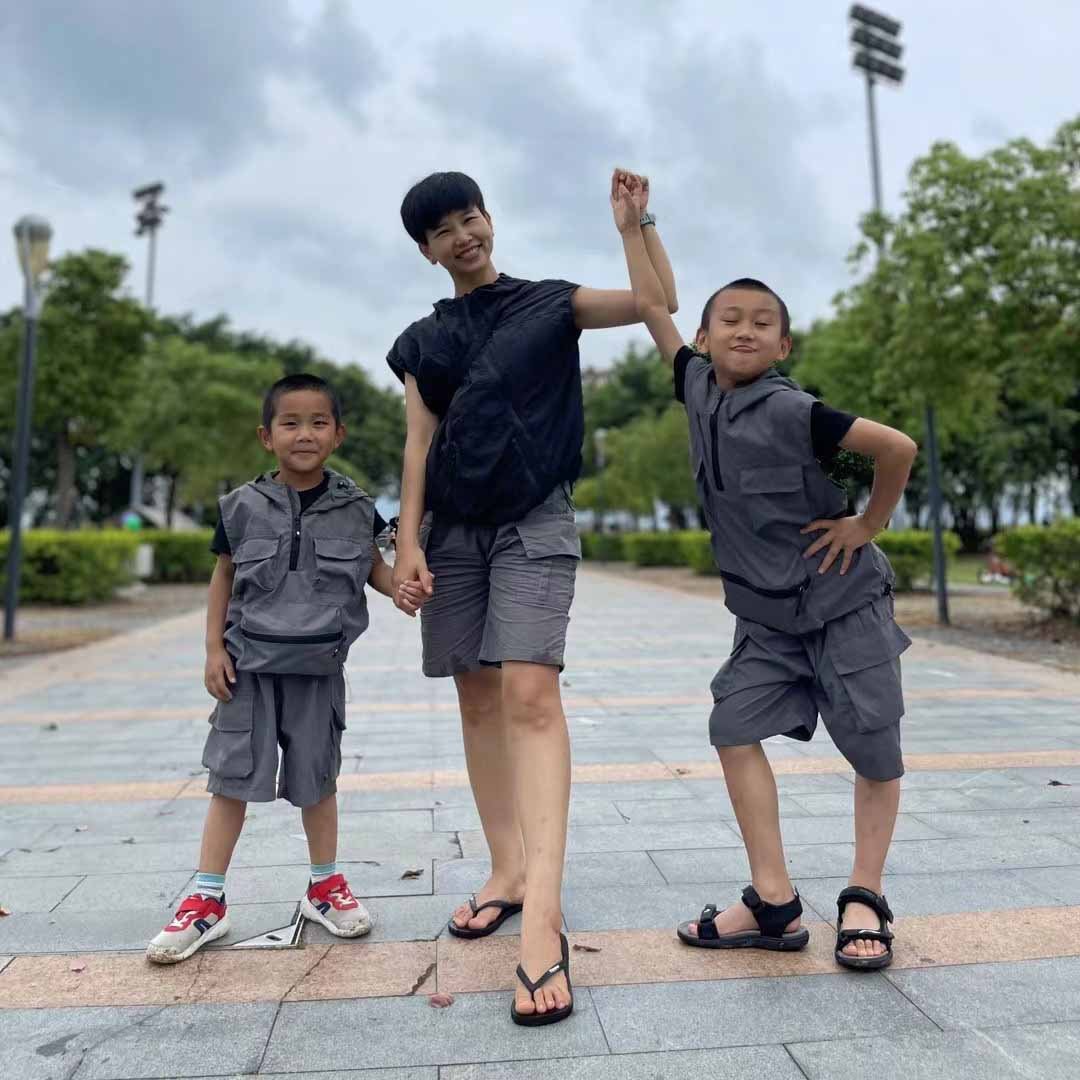

A live fit model is essential because activewear is built for movement. The model performs dynamic tests—squatting, stretching, running—to reveal problems that a static mannequin cannot. This real-world feedback on comfort, security, and fabric behavior is absolutely critical.

I insist on a fit session for every new style we develop at Wearzio. A mannequin can show you how a garment hangs, but it cannot tell you if a seam is scratching the skin. It cannot tell you if the waistband rolls down when you bend over. It cannot do a squat to check if your leggings become transparent. I will never forget a fit session for a new sports bra. On the mannequin, it looked perfect. But when our fit model did a jumping jack, she immediately pointed out that the straps were digging into her shoulders. We were able to adjust the strap placement and angle before making 5,000 units. That five-minute test saved the brand from a product disaster.

Dynamic Testing for Real-World Performance

A fit session is a structured process where we look for specific issues related to active performance. We ask the model to move through a series of exercises designed to stress the garment.

- The Squat Test: This is non-negotiable for leggings. The model performs a deep squat while we check if the fabric becomes sheer or if the waistband slides down.

- The Overhead Reach: For tops and sports bras, the model reaches their arms straight up. We check to see if the garment rides up, exposing the midriff, or if movement feels restricted across the back and shoulders.

- Running in Place / Jumping Jacks: This tests for overall security. Do straps stay in place? Does anything bounce uncomfortably? Does any part of the garment chafe?

The feedback from the model is pure gold. They provide comments like, "I can feel the seam under my arm," which we then translate into a technical adjustment. This dynamic testing is the final and most important step to bridge the gap between a good design and a great product.

Conclusion

Achieving the perfect fit is a meticulous process. It requires harmonizing your fabric choice, creating a professional grade rule, and testing the final product on a moving human body.

.png)