Expert

Cut & Sew

Manufacturing

Advanced fabric cutting and precision sewing techniques for premium activewear. From pattern making to final stitching, we deliver unmatched quality and consistency.

Our Cut & Sew Advantages

Combining traditional craftsmanship with modern technology to deliver superior activewear manufacturing solutions.

Laser Cutting Precision

Advanced laser cutting technology ensures ±0.5mm accuracy for consistent pattern pieces and minimal fabric waste.

- • Clean, sealed edges

- • Complex pattern capability

- • Zero fraying guarantee

4-Needle 6-Thread Seaming

Professional-grade seaming techniques provide superior stretch recovery and durability for high-performance activewear.

- • Enhanced elasticity

- • Flat-lock finish options

- • Reinforced stress points

Smart Pattern Matching

AI-assisted pattern optimization maximizes fabric utilization while maintaining perfect alignment and symmetry.

- • 15% material savings

- • Perfect stripe/print matching

- • Automated nesting

Seamless Construction

Innovative bonding techniques create smooth, comfortable seams that eliminate chafing and irritation.

- • Heat-bonded seams

- • Ultrasonic welding

- • Chafe-free construction

Multi-Layer Assembly

Specialized techniques for complex garments with integrated support, padding, and performance features.

- • Built-in bra construction

- • Compression zone integration

- • Moisture management layers

Rapid Prototyping

Quick sample production with 3D visualization and fit testing capabilities for faster product development.

- • 7-day sample delivery

- • 3D fit simulation

- • Virtual try-on testing

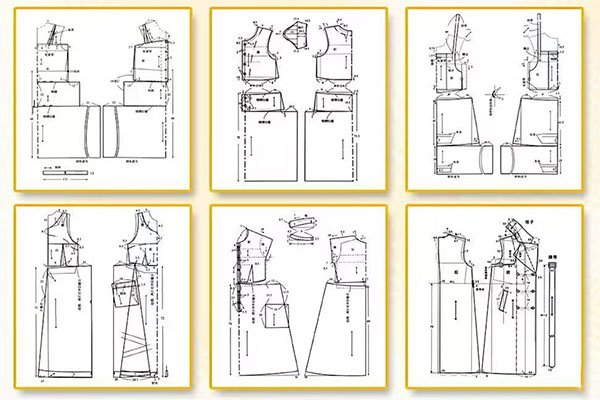

Manufacturing Process Steps

From initial design to final inspection, our systematic approach ensures consistent quality and efficient production.

Pattern Development

Technical pattern creation with precise measurements and grading for all sizes. Digital pattern optimization ensures perfect fit and minimal waste.

- CAD pattern design and grading

- Fit testing and adjustments

- Size chart optimization

Precision Cutting

Advanced laser and automated cutting systems ensure consistent accuracy and clean edges for every piece.

- Laser cutting technology

- Automated fabric spreading

- Quality control inspection

Expert Sewing

Skilled craftspeople using specialized machines for activewear construction, ensuring durability and comfort in every seam.

- 4-needle 6-thread construction

- Flat-lock seaming options

- Reinforced stress points

Quality Control

Comprehensive multi-stage inspection process ensuring every garment meets our strict quality standards before packaging.

- Triple-layer QC inspection

- Fit and function testing

- Final packaging preparation

Our Quality Promise

We stand behind every stitch with comprehensive quality guarantees and industry-leading certifications.

Zero Defect Guarantee

Every garment undergoes rigorous inspection. We guarantee zero manufacturing defects or full replacement at no cost.

Batch Consistency

Advanced color matching and precise measurements ensure perfect consistency across entire production runs.

Performance Testing

All activewear undergoes stretch, wash, and wear testing to ensure long-lasting performance and durability.

.png)