Seeing your brand's reputation ruined by faulty zippers or crooked seams is a nightmare. These small mistakes lead to big losses. I'll show you how to prevent them.

Implement a multi-stage QC process. First, inspect raw materials upon arrival. Second, conduct in-line inspections during sewing. Finally, perform a rigorous final inspection on a sample of finished goods using an AQL standard before shipment. This layered approach catches errors early.

I've seen it happen. A brand invests everything into a new collection, only to receive a shipment full of defective products. It's heartbreaking, and it is completely avoidable. In my years running Wearzio, from a small studio to a global partner, I've learned that Quality Control (QC) is not a final step. It is a mindset that must be present through the entire production journey. It is the only way to protect your investment, your brand, and your relationship with your customers. Let me break down how we make this happen.

What Are the Key Checkpoints in a Garment Inspection?

You receive a shipment, and everything looks okay at first glance. But soon, customers start complaining about odd sizing and loose threads. You need a system to catch these hidden flaws.

Key checkpoints are measurements, materials, construction, and finishing. Check if the garment matches the spec sheet's dimensions. Verify fabric and trim quality. Inspect seam strength and stitching. Finally, check for visual defects, cleanliness, and proper packing.

A quality inspector's most important tool is the technical package, or "tech pack." This document is the bible for your product. It contains every single detail, from the fabric composition to the length of the stitches. Our QC process is built around verifying that the physical garment is a perfect match for the tech pack. I once worked with a brand whose tech pack had a small error in the sleeve length measurement. Our in-line measurement check caught the mistake after only a few dozen pieces were made. We paused production, confirmed the correct measurement with the client, and adjusted. That simple checkpoint saved their entire order of 2,000 tops from being defective.

The Four Pillars of Garment Inspection

A thorough inspection looks at four distinct areas. Missing any one of these can lead to problems. We train our teams to be experts in all four.

- Measurements & Fit: We lay the garment flat and measure critical points, comparing them against the tolerances in your tech pack.

- Materials & Trims: We check that the correct fabric, thread, zippers, and drawstrings were used. We also look for fabric defects like snags or discoloration.

- Construction & Workmanship: This involves checking the seams, stitches, and overall assembly. Are the stitches even? Are the seams strong? Is everything sewn neatly?

- Finishing & Packing: This is the final check for any visual issues like uncut threads, stains, or printing errors. We also ensure garments are folded and packed according to your requirements.

| Inspection Pillar | What We Check | Why It Matters |

|---|---|---|

| Measurements | Dimensions (e.g., chest, length, waist) vs. spec sheet. | Ensures consistent sizing and fit for all your customers. |

| Materials | Correct fabric, color, trims, and logos. | Guarantees the garment performs and looks as designed. |

| Construction | Seam strength, stitch type (e.g., flatlock), bartacks. | Prevents the garment from falling apart and ensures comfort. |

| Finishing | Uncut threads, stains, proper labeling, packing. | Creates a professional first impression for the customer. |

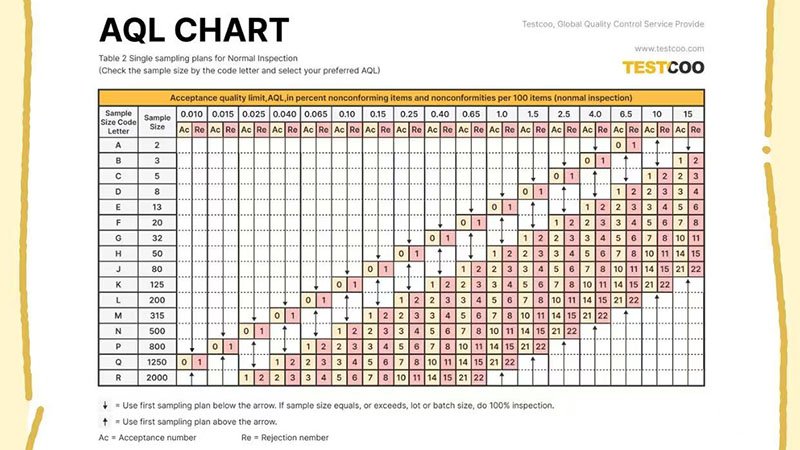

What is AQL and How Does It Work for Apparel?

Inspecting every single garment in a large order is impossible and expensive. But how do you decide how many to check? Guessing can lead to defective products slipping through to your customers.

AQL, or Acceptance Quality Limit, is a statistical sampling method used worldwide. It tells you how many garments to inspect from an order and the maximum number of defects allowed in that sample. It provides a standardized, efficient way to assess the quality of the entire batch.

When I first learned about AQL, it was a game-changer. It replaced guesswork with statistics. It's not a guarantee of a 100% defect-free order. Instead, it’s a mutual agreement between the brand and the manufacturer on what level of quality is acceptable. For example, AQL 2.5 is a common standard in the apparel industry. This means you are willing to accept lots that have, on average, no more than 2.5% defective items. For a brand owner like Alex, understanding this allows you to have an intelligent conversation about risk and cost. A stricter AQL (like 1.0) means more inspection and higher costs, but less risk. A looser AQL is cheaper but riskier. My job is to help you find the right balance for your brand.

Understanding Defect Levels

AQL inspections classify defects into three categories. This helps prioritize what is truly a problem.

- Minor: A small flaw that is unlikely to be noticed by the customer or affect the garment's use (e.g., a single uncut thread inside).

- Major: A flaw that a customer would likely notice and might cause them to return the item (e.g., a crooked seam, noticeable stain).

- Critical: A defect that is unsafe or could cause harm (e.g., a broken needle left in the garment) or makes the product unusable. A single critical defect means the entire batch fails inspection.

| Defect Type | Example in Activewear | Consequence |

|---|---|---|

| Critical | A sharp edge on a zipper pull. | The entire order is rejected and must be 100% reinspected. |

| Major | Leggings are see-through when they should be squat-proof. | The order may be rejected or require rework. |

| Minor | A care label is slightly crooked but still readable. | The order is typically accepted. |

How Can You Manage QC When Manufacturing Overseas?

Your factory is thousands of miles away. You cannot just walk onto the factory floor to check progress. This distance creates anxiety and a feeling of lost control over the quality of your product.

Manage remote QC with a transparent manufacturing partner who provides regular updates. Use detailed tech packs, approve pre-production samples meticulously, and consider hiring a third-party inspection service for final checks. Clear communication and trust are your most powerful tools.

This is the exact problem I built Wearzio to solve. The fear of the unknown is the biggest challenge for overseas production. That is why we operate as your trusted team on the ground. The most critical step is the Pre-Production Sample (PPS). This is the final, perfect sample made with the actual bulk fabric and trims. Once you approve the PPS, it becomes our physical contract. We use it as the gold standard against which every single production piece is measured. During production, we provide constant updates with photos and videos of the line. For us, transparency is not a buzzword; it is the foundation of a successful partnership. You should feel as confident as if you were standing right here with me.

Your Toolkit for Remote Quality Assurance

You have several tools at your disposal to ensure quality from afar. Combining them gives you the best protection.

- The Perfect Tech Pack: As I mentioned, this is your blueprint. The more detail you include, the fewer questions there will be.

- The Pre-Production Sample (PPS): Do not rush this step. Scrutinize the PPS. Wash it, wear it, test it. Your approval gives the green light for bulk production.

- A Transparent Partner: Work with a manufacturer who is eager to communicate. They should be your eyes and ears.

- Third-Party Inspection: For very large orders or when you need an extra layer of security, you can hire an independent inspection company. They will go to the factory and perform an AQL inspection on your behalf.

| QC Method | Pros | Cons |

|---|---|---|

| Relying on a Transparent Partner | Cost-effective, builds trust, faster communication. | Requires a high level of trust in your partner. |

| Hiring a Third-Party Inspector | Provides an unbiased, independent report. | Adds cost ($300+ per day), can add delays. |

Conclusion

A robust QC process is not an expense, but an essential investment. It protects your brand, satisfies your customers, and ensures the long-term success of your sportswear line.

.png)