Struggling to turn your activewear vision into reality? You have great designs but finding a reliable manufacturing path feels impossible. Let's build your brand, step by step.

To create stand-out activewear, define your niche and create a detailed tech pack. Then, select high-performance fabrics that match your brand's identity and partner with a manufacturer who understands your vision and offers transparent communication and quality control throughout the production process.

I've seen many passionate brand owners start with a powerful idea. They want to create something special, something that genuinely performs. But the journey from a design sketch to a finished garment can be filled with unexpected challenges. It's about more than just a logo; it's about making smart choices right from the beginning. Let's break down that journey so you know exactly what to focus on.

What's the First Step in Designing Your Activewear Line?

Your design ideas are clear in your head, but factories don't seem to understand them. Miscommunication leads to bad samples and wasted money. Let's translate your vision into their language.

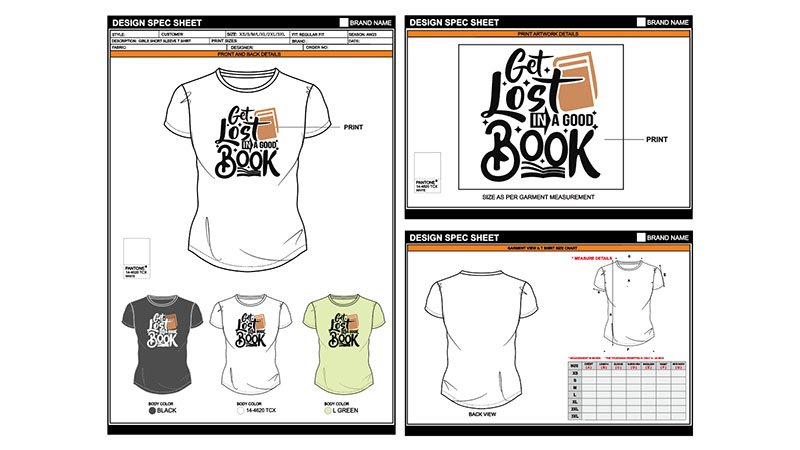

The first step is creating a detailed "tech pack." This document is your design's blueprint. It contains all technical specifications, from measurements and fabric types to stitching details. This ensures your manufacturer understands exactly what you want, minimizing errors and saving time.

A good tech pack is the foundation of a smooth production process. From my years of experience, a weak tech pack is the number one cause of problems. It's not just a sketch; it's a comprehensive guide. It removes guesswork for the pattern makers and sewing teams. You must make sure your tech pack includes these key elements.

- Technical Drawings (Flats): These are clear, detailed sketches of the front, back, and side of your garment. You should include callouts for specific details like seam placements or zipper types.

- Bill of Materials (BOM): This is a complete list of all materials needed. It includes the main fabric, any lining, threads, zippers, drawstrings, and branded labels.

- Graded Size Chart: This provides the precise measurements for your entire size range, not just a sample size.

- Construction Details: These are instructions on stitching, seam types, and any special techniques required. For activewear, this might specify flatlock seams for comfort.

A strong tech pack saves you both time and money. It ensures the first sample we create is much closer to your final vision.

How Do You Choose the Right Fabrics for Performance and Style?

Your activewear looks great but doesn't perform well during a workout. Customers complain about poor sweat-wicking or lack of stretch. Your fabric choice can fail your brand's promise.

Choose fabrics based on your product's specific function. For high-intensity workouts, select moisture-wicking and four-way stretch blends like Nylon/Spandex. For lifestyle pieces, prioritize softness and breathability with materials like Modal or Bamboo. Always request fabric swatches to test feel and performance.

The fabric is the heart of your activewear. It dictates comfort, durability, and how your customer feels wearing it. I started my career working hands-on with materials, and I know that the right choice is critical. For a brand owner focusing on performance, you need to understand the trade-offs. You want stretch but also compression. You need it to be lightweight but also durable. Here is a simple breakdown of common choices I work with every day.

| Fabric Type | Best For | Key Properties |

|---|---|---|

| Nylon/Spandex | Leggings, Sports Bras | Excellent stretch & recovery, durable, compressive feel |

| Polyester | T-shirts, Shorts | Very durable, holds color well, great moisture-wicking |

| Merino Wool | Base Layers, Hiking | Natural odor resistance, thermoregulating, soft on skin |

| Modal/Tencel | Yoga Tops, Loungewear | Extremely soft, very breathable, often sustainable |

Always ask your manufacturing partner for sample swatches. Feeling the fabric is the only way to truly know if it aligns with your brand's promise of premium quality.

What Should You Look for in a Custom Apparel Manufacturer?

You found a cheap manufacturer, but they miss deadlines and communication is terrible. Your production is stalled, and you feel powerless. You don't need a supplier; you need a partner.

Look for a manufacturer who offers transparent communication, fair MOQs (Minimum Order Quantities), and a proven track record in activewear. Ask for case studies or references. A true partner will guide you through the process and value your brand’s vision as their own.

Finding the right manufacturing partner is like a business marriage. The success of your brand depends heavily on this relationship. When I expanded Wearzio from a small studio to a global partner, I built it on the principle of partnership, not just transactions. Brand owners need more than just a factory that can sew. You need expertise and reliability. When you are looking for potential partners, go beyond the price quote. Ask them these important questions:

- What are your MOQs, and are they flexible for new brands?

- Can you share examples of similar activewear you've produced before?

- What is your quality control process, from sourcing fabric to final inspection?

- Who will be my main point of contact, and how will we communicate?

A good partner will be happy to answer these questions. They will be invested in helping you succeed because your success is also their success.

How Can You Manage Production and Ensure Quality Control?

You approved a perfect sample, but the final bulk order is different. The fit is off, and the colors are wrong. Now you're stuck with inventory you can't sell.

Manage production by establishing clear checkpoints. Always approve a Pre-Production Sample (PPS) before starting bulk manufacturing. This sample is made with the final fabrics and trims. Maintain regular communication with your manufacturer and request progress updates during the production run.

Quality control is not just a final step; it is a continuous process. From my experience on the factory floor, I can tell you that catching a small issue early saves a massive headache later. The most critical step is the Pre-Production Sample, or PPS. This is your golden standard. You must test it thoroughly. Wash it, wear it for a workout, and stretch it. Once you approve the PPS, your manufacturer should use it as the benchmark for the entire bulk order. Here is a typical production flow I use to help brands manage the process clearly:

- Step 1: Proto Sample: An initial sample to check the design and basic fit.

- Step 2: Fit Sample: We make adjustments based on your feedback on the proto.

- Step 3: PPS Approval: The final sample is approved before any bulk production begins.

- Step 4: Bulk Production: Manufacturing starts. I always suggest asking for in-line inspection reports.

- Step 5: Final Inspection: A final quality check is done before the goods are packed and shipped.

Constant communication during these stages is the key to ensuring your final product matches your vision perfectly.

Frequently Asked Questions

How much does it cost to start a custom activewear line?

This is a common question, but there is no single answer. Your total cost will depend on fabric quality, design complexity, order quantity (MOQ), and branding details. From my experience, your investment includes design development (tech packs), sampling, the cost per garment for bulk production, shipping, and import duties. I advise new brands to budget for each of these stages separately.

What is a realistic timeline from design to delivery?

A realistic timeline from a finalized tech pack to having the products in your hand is typically 3 to 6 months. This can be broken down: fabric sourcing and sampling can take 4-8 weeks, bulk production usually takes 6-10 weeks, and international shipping can add another 1-6 weeks depending on the method. It's important to build buffer time into your launch plan.

What are my options if I can't meet high MOQs?

This is a major challenge for new brands. MOQs often exist because fabric mills have their own minimums. However, many modern manufacturers, like us at Wearzio, try to be flexible. I always suggest starting small and focused. Instead of five different styles, launch with one or two core products in a few colors. This concentrates your investment and makes it easier to meet a reasonable MOQ.

How can I make my activewear brand more sustainable?

Sustainability is a powerful way to connect with customers. You can start by choosing sustainable fabrics like recycled polyester, recycled nylon, or organic cotton. Another way is to work with manufacturers who have certifications for ethical labor practices and environmentally friendly processes. Even small choices, like using biodegradable packaging, can make a big difference for your brand's story.

Conclusion

Creating custom activewear is a detailed journey. With a clear design, the right fabrics, and a true manufacturing partner, you can confidently build a brand that customers love.

.png)